An adiabatic cooler applies the principle that when the pressure applied on a parcel of air is reduced, the air in the parcel is allowed to expand; as the volume increases, the temperature falls as its internal energy decreases. In an adiabatic air cooler air is drawn across the coil by the fan. As the warm air encounters the wetted pad or water spray, the air temperature is reduced adiabatically thus allowing sensible cooling of the coil below the ambient dry bulb temperature.

When the ambient temperature is below the set-point for the fluid being cooled, the cooler operates in dry mode, with the fans drawing ambient air across the coil to cool it. As the ambient temperature rises, it can no longer achieve the desired cooling and the cooler switches to adiabatic mode to reduce the temperature of the incoming air.

With intelligent control it is possible to balance the use of the fans and water delivery to achieve either reductions in water consumption or energy.

What is Adiabatic Cooling?

Adiabatic Cooling occurs when the pressure on an adiabatically isolated system is decreased, allowing it to expand, thus causing it to do work on its surroundings. When the pressure applied on a parcel of air is reduced, the air in the parcel is allowed to expand; as the volume increases, the temperature falls as its internal energy decreases.

How Does Adiabatic Cooling Work?

Adiabatic Cooling occurs when the pressure on an adiabatically isolated system is decreased, allowing it to expand, thus causing it to do work on its surroundings. When the pressure applied on a parcel of air is reduced, the air in the parcel is allowed to expand; as the volume increases, the temperature falls as its internal energy decreases.

What’s the Difference Between Adiabatic and Evaporative Cooling?

Evaporative cooling is a natural process when heat is applied to water it changes from a liquid to a vapour and when evaporation occurs, the heat is taken from the water that remains in liquid state resulting in cooler water.

Adiabatic Cooling occurs when the pressure on an adiabatically isolated system is decreased, allowing it to expand, thus causing it to do work on its surroundings. When the pressure applied on a parcel of air is reduced, the air in the parcel is allowed to expand; as the volume increases, the temperature falls as its internal energy decreases.

In summary, Evaporative cooling, as used by a cooling tower rejects heat from the process fluid and adiabatic cooling as used by an adiabatic cooler rejects heat from the stream of air passing into the cooler.

What’s the Difference Between Adiabatic Towers and Cooling Towers?

In an open-circuit cooling tower, the water to be cooled is distributed over a fill pack at the same time as a fan system moves air through the fill pack. This causes a small portion of the cooling water to evaporate which reduces the temperature of the remaining circulating water. The cooled water is collected at the base of the cooling tower and then recirculated to the plant or process needing to be cooled. The warm, humid air is discharged from the tower into the atmosphere.

We’ve created an in-depth article; FAQ’s Adiabatic Coolers vs Open Circuit Cooling Towers. If you have any questions regarding the differences and benefits of each system, you’ll most likely find the answer over in the FAQ.

Closed circuit cooling towers and evaporative condensers use the same evaporative cooling principle as open circuit cooling towers but incorporate a heat exchanger in which a fluid is cooled by a secondary recirculating system that distributes water over the heat exchange coil and a portion of this water is evaporated. The heat to evaporate the water is taken from the coolant, with the heat being transferred to the water vapour in the air stream, which is discharged into the atmosphere in the same way as an open circuit cooling tower.

An adiabatic cooler applies this principle to the air that is drawn across the coil by the fan. As the warm air encounters the wetted pad or water spray, the air temperature is reduced adiabatically thus allowing sensible cooling of the coil below the ambient dry bulb temperature.

The majority of the water used to cool the air is evaporated to the atmosphere and is therefore not recirculated It is important, however to understand the water source as a stored or recirculated water source can pose significant legionella risk and can affect the legislative requirements.

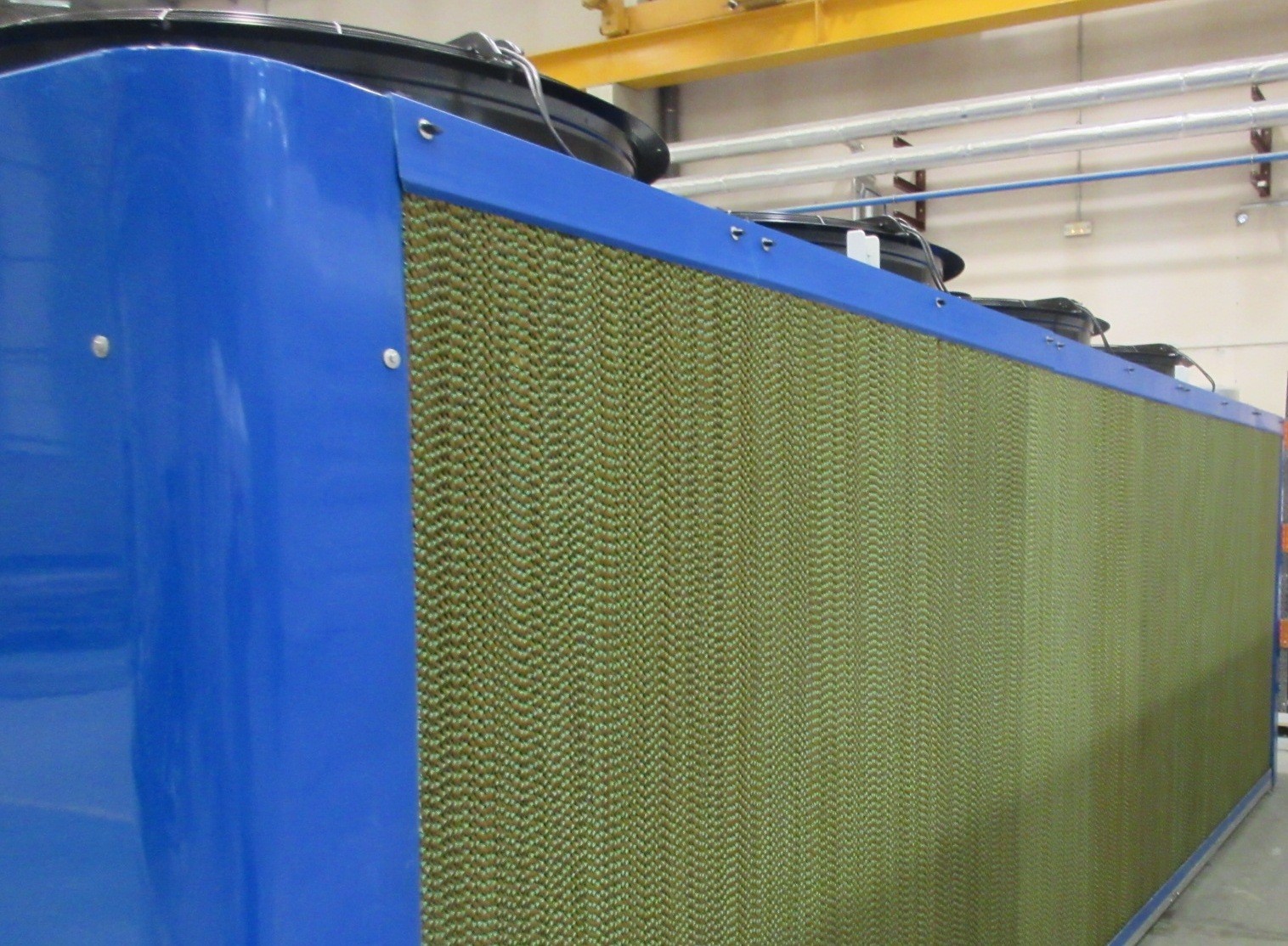

There is a multitude of designs of adiabatic coolers ranging from crude retro fitting of a spray system to an existing dry air cooler through to an intelligently controlled wetted pad or originally installed spray system.

Whatever the system in place, they can broadly be grouped into three distinct design categories:

- Coolers that spray water towards the coil

- Coolers that spray water away from the coil into the air stream

- Coolers that trickle water over a medium through which the air passes

The selection of the design type can be important as they pose different levels of risk and therefore different legislative requirements resulting in varying levels of ongoing management and maintenance costs.

Learn More about Adiabatic Coolers

If you would like some more detailed information, head on over to our article Considerations When Selecting an Adiabatic Cooler. There you’ll find a detailed breakdown of Adiabatic Coolers with all the information you could need to make the right decision for your company.

Lucy keeps the well oiled machine of Vistech Cooling running smoothly. She has close to a decade of experience working in the industry and creates industry-leading content that provides necessary information but also deeper insights into the field most people may not have considered.